On a sunny June afternoon, I visited Dr. Christina Agapakis at the Ginkgo Bioworks offices in Boston’s Innovation and Design Building (also the future home of America’s Test Kitchen!). Ginkgo Bioworks, the “The Organism Company,” engineers custom microbes by genetically modifying organisms like yeast to produce particular flavor and aroma compounds during the fermentation process. During my visit, Agapakis talked about the cutting-edge field of synthetic biology, and how it might impact the future of industries from flavors and foods to cosmetics and perfumes.

Cook’s Science: Synthetic biology is a not a field most people are familiar with. Can you explain, in a nutshell, what you and your colleagues do here at Ginkgo Bioworks?

Christina Agapakis: We’re interested in how to build and make stuff with biology. And it grows in this way that’s inherently sustainable and part of ecosystems. We see biology as a better way to make stuff and we see it impacting a lot of different industries as a result. At Ginkgo, the focus of the company has been on making biology easier to design, easier to engineer, and building a platform on which biological engineers can use biology to build something new.

A lot of our business today is in cultured ingredients, which is the idea that you can genetically engineer yeast to produce [specific molecules or compounds] during the process of fermentation. These are often flavors or fragrances, specialty ingredients, or even nutritional ingredients.

CS: Our team at Cook’s Science and much of the general public, is familiar with yeast and with using bacteria to ferment pickles, beets, sauerkraut, etc. How does that sort of fermentation relate to the fermentation you’re doing at Ginkgo Bioworks?

CA: It’s the same biochemical process . . . the same transformation of sugar into something else by the yeast cells. When you’re talking about beer, that’s yeast taking the sugars from barley or other grains and transforming them into alcohol, carbon dioxide, and all the flavors you get along with the beer. What we do [at Ginkgo Bioworks] is start with that process and say: What enzymes can we take from other plants or other organisms and add them to the yeast [by modifying the yeast’s DNA] so that during fermentation, some of the energy from the sugar is going to create another product as well as the alcohol and carbon dioxide.

One product that’s been made using fermentation for a long time is amino acids, especially amino acids used in animal feed. Those are produced in huge vats on a huge scale; a scale that would not have been possible if you were trying to purify amino acids from proteins from another food source. But there are other kinds of products [made using fermentation], especially in fragrances and cosmetics. There are a lot of compounds present in very small quantities in plants and extracting them has led to a situation where [companies] have farmed or harvested those plants to near-extinction, so now the resource is constrained. Now, [with synthetic biology] there’s the opportunity to be able to synthetically make these compounds at a scale that wouldn’t otherwise be possible.

CS: What are some industries or companies you’ve designed microbes for?

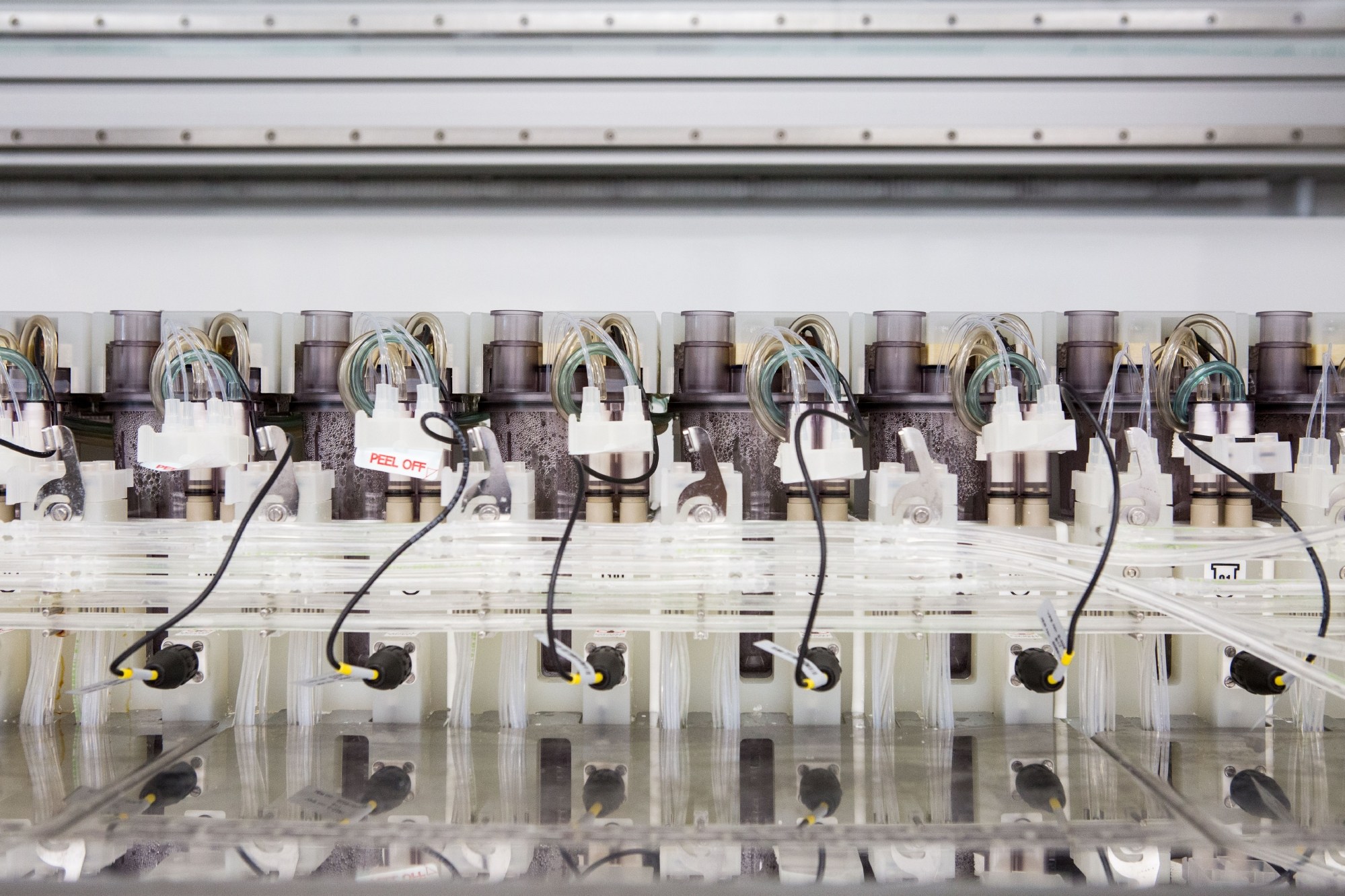

CA: We work with companies like Robertet, which is a flavor and fragrance company, on different ingredients. [Editor’s Note: For example, Ginkgo and Robertet are currently working to insert DNA sequences into yeast so they will produce rose scent compounds during fermentation.] During development here in the lab, we do fermentation in about 250-milliliter containers, about the size of a soda can. When a product eventually goes to full, commercial-scale fermentation, it can grow to 50,000 liters in just a couple of days, which shows you what biology can do when the yeast itself acts like the factory that makes these molecules or compounds.

CS: How would you define “synthetic” in the context of what you’re doing at Ginkgo Bioworks? Aren’t yeast technically natural organisms?

CA: That’s a really good question and a really hard question. I think how we define synthetic is so tied up in all of these philosophical and historical narratives and arguments. The organisms we’re working with are pretty close to naturally-occurring yeasts and other microbes but they have been modified. We have added or taken away genes from their genomes. And I think that difference is important . . . The question of how different [are these organisms] and at what point do they cross [the line between natural and synthetic], I think that’s something people have to decide for themselves.

CS: How do you see synthetic biology intersecting with the culinary world: restaurants, chefs, home cooks, even consumers at the grocery store?

CA: There’s a lot that is happening, or has happened, and a lot that will happen in the future. Many ingredients or enzymes are already produced using fermentation or biotechnology, things that we don’t necessarily know or think about . . . enzymes that are used in cheese production, brewing, baking, or other kinds of preservation or transformation of food, [many of] those are already made using biotechnology. There’s a lot of potential for synthetic biology to improve the efficiency of those enzymes or find new enzymes that will enable new tastes or send things in new directions.

CS: Is there a example of the intersection between synthetic biology and food or cooking that struck you as particularly interesting?

CA: Cheese. You need enzymes to make cheese. An enzyme called chymosin is present in rennet [a complex of enzymes used to coagulate milk in cheesemaking]. Rennet, historically, has come from the stomach lining of calves, but now the majority of rennet used in cheese production comes from genetically modified fungi that are able to produce that enzyme, instead of extracting it from an animal. We’re working on other enzymes that are used in cheese production—for guiding the flavor of different types of cheese—that are also often extracted from animals. So we’re looking at ways of making them [using synthetic biology instead].

CS: So, I have to ask you about the cheese project. How did you come up with the idea to use bacteria cultured from humans to make cheese? What did you hope to learn from the experiment?

CA: About seven years ago, as a graduate student, I was part of a project called Synthetic Aesthetics, which paired synthetic biologists with artists to explore the potential connections between science and technology, and art and design. My partner was Sissel Tolaas, an odor researcher based in Berlin . . . her work is about perceiving smells in different ways and being aware of how our prejudices and emotions dictate whether we say a smell is good or bad. I was working on microbes and synthetic biology and was particularly interested in microbial communities. There are microbial communities on [human skin] that make body odors—that’s where [those odors] come from. So we started asking what are those microbes, what are the chemicals they produce, and what can we learn about them. And as we started to do that research, looking for papers on the species of bacteria [found on human skin], everything was turning up cheese. And then we realized, oh wow, there’s a connection: There’s a cheese that smells like feet!

We started digging into what people already know about this connection . . . and then at one point we said, “well, let’s just make some cheese [using bacteria cultured from people] and see what happens.” It gets a very visceral reaction, because it does feel wrong, I think, to have the bacteria go from your feet to your food. That was a feeling we wanted to explore and challenge. We wanted to ask, if we do domesticate bacteria more, if people are using microbes in their home cooking more and more . . . how is that going to change our relationship to them? How is it going to change our relationship with our own bodies and the bacteria there? Will we still draw these kinds of boundaries around ‘good’ and ‘bad’ bacteria, or will those shift, too? [Editor’s Note: I know you’re curious . . . Agapakis only sampled the cheese cultured from her own bacteria.]

CS: Tell us about your role as creative director at Ginkgo Bioworks. That’s not a title we often associate with biotechnology companies.

CA: Creative teams at technology companies [like Ginkgo Bioworks] are really thinking about the edge between science and technology and the world. How do you communicate the news stories to the general public? How do you package the stories? How do you create products that are going to make sense in the real world?

CS: Do you have a favorite microbe?

CA: [Laughing] I love them all equally. There are some bacteria that make these really gorgeous patterns as they grow [on cultured media]. It’s called Paenibacillus vortex—they make these just outrageous patterns as they spread over Petri dishes, it’s really beautiful. There’s also a [genus of] photosynthetic bacteria called Anaebena, which can do a lot of really interesting things. [They’re] also kind of multicellular in that they make these really long filaments of cells. I love bacteria that blur the boundary between single cellular and multicellular . . . when bacteria have multicellularity and these complex relationships with each other, I think it’s really beautiful.

CS: Where do you see the field of synthetic biology heading in the next 5-10 years? What kinds of products might we be eating, wearing, or using that were developed using genetically modified microbes?

CA: I think we’ll start to see new materials. [For example], there’s a company called Bolt Threads that’s producing spider silk using yeast. I think we’ll also see new flavors and new enzymes making an impact along the supply chain. I also hope to see new questions being asked about how synthetic biology can affect the culinary world or people who are trying to ferment things at home. It’s fun to think about what a chef or a home pickler would do with a specific microbe, where would they take it? This is an important element to my role . . . I think the future emerges from how people interact [with the technology] . . . using their creativity and intuition for food or flavor to take it in a new direction. There is the potential to ask: What microbes are there? How can we control them differently to add new dimensions to flavor? And then the sky’s the limit because anything can be fermented.

This interview has been condensed and edited.

Photography by Kevin White.